RELIAHEAT® PTC Technology

Revolutionizing heating applications…

Positive Temperature Coefficient (PTC) ink is a self-regulating thermally conductive printable ink that is dramatically changing the way heating applications are manufactured. Self-regulating PTC ink can be used to design heating elements that heat quickly to equilibrium temperature and stabilize without external controls. Eliminating the need to use traditional wires that can overheat, burn, melt, or cause damage, PTC ink is an exciting technology with the potential to increase safety and reliability for a wide variety of heating applications.

BENEFITS

Compared to traditional heating elements that utilize wires and coils, Reliaheat® screen-printed PTC heaters and warming elements provide a number of substantial advantages.

PERFORMANCE ADVANTAGES

Increased safety. Reliaheat PTC heaters are self-regulating to a specific threshold temperature, inherently preventing failures due to overheating, burning or melting.

Simple and lightweight. Bulky external diagnostics and controls are eliminated, as Reliaheat PTC heaters run open-loop, using unregulated AC or DC power.

Designed to temperature. Reliaheat PTC heaters can be designed for any temperature up to 120⁰C, without any external controlling device.

Uniform heat. The printed heater area provides consistent temperature and even heat transfer, eradicating irksome “hot spots”.

Rapid heating. Reliaheat PTC heaters immediately draw full power, quickly reaching target temperature.

Reduced power consumption. Unlike traditional heaters, Reliaheat PTC heaters dynamically adjust power consumption for more efficient management.

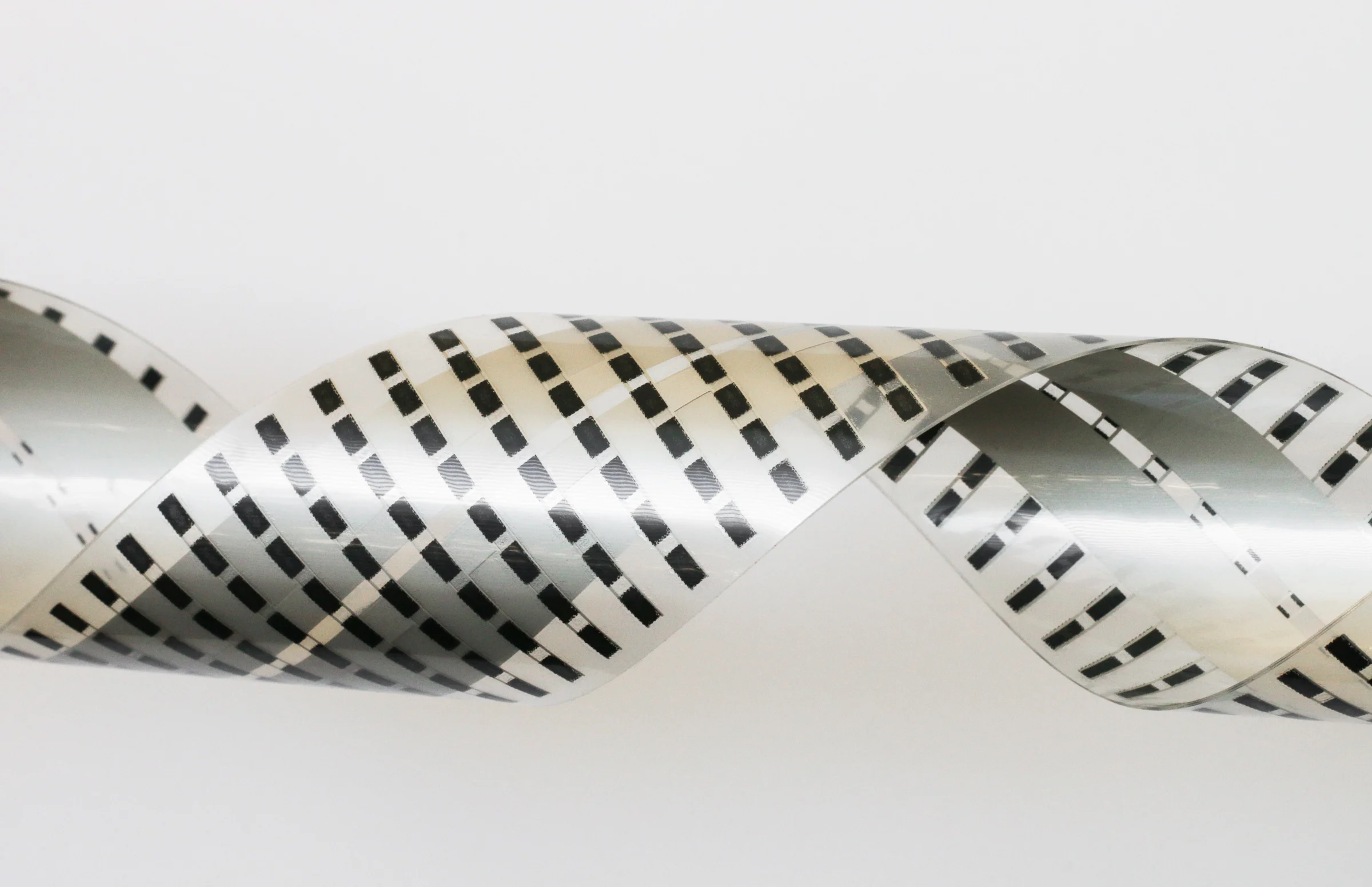

Thin and flexible. The proprietary Reliaheat PTC ink application utilizes polyester substrates that allow for low-profile, thin heaters that can be designed for a variety of sizes and shapes.

Durable in harsh environments. Reliaheat PTC heaters are corrosion and water-resistant.

Silent operation. Unlike traditional heating elements that may emit noise, Reliaheat PTC heaters generate heat silently.

Environmentally-friendly. Both the manufacturing process and materials for Reliaheat PTC heaters are safer for the environment than traditional heating elements.

NEMA 4X / IP66. Reliaheat is designed and manufactured to NEMA 4X / IP66 standards, providing watertight protection against moisture and dirt, as well as additional corrosion resistance (tested against ammonia, vinegar, bleach, soap water and hydrogen peroxide).

COST-EFFECTIVE

Focused prototyping. Reliaheat proprietary software reduces multiple trial and error prototype runs, resulting in reduced research, design and development costs.

Lower material cost. Compared to traditional heating elements such as copper, Reliaheat PTC heaters are substantially less expensive.

Highly-efficient production. The Reliaheat screen-printing process is far more cost-effective than wire or coil applications, reducing overall project cost.

WHY RELIAHEAT?

the reliaTRACE® double-sided advantage

For 30 years, Reliatrace® has been producing the industry’s most reliable membrane switches with double-sided polymer circuitry (D/SPC®), and we’re excited to now offer this proprietary technology in our custom Reliaheat® PTC heaters.

Our unique ability to print on both sides of the substrate provides several advantages over single-sided flexible heater circuits:

Ability to produce a more even heat transfer using a smaller footprint

More heat generated per square inch, resulting in higher heat density, due to the bus bars being placed on the bottom-side of the circuit

Higher heat output capabilities

Multi-zone heat capability, with different temperature zones designed into a single circuit

Ability to conform to convex/concave surfaces, including handle grips, pipes, and contoured body features

Easier to make water-resistant, as the efficient use of space in double-sided circuitry provides more room for gasketing options

Reliaheat PTC heaters have been comprehensively tested for reliability and efficiency to ensure the common failure points of competitive technologies have been eliminated. With established PTC ink manufacturer and material supplier partnerships, Reliatrace is able to offer clients a wide variety of options when designing their custom Reliaheat PTC heater or warming element.

Potential Applications

· Medical / Healthcare

· Commercial

· Industrial

· Residential

· Consumer

· Wearables

· Marine

· Food & Beverage

· Mobile equipment